Flexible silicone soap mold

Dimensions: 23.5 cm x 8 cm x 24.4 cm

They are reusable and dishwasher safe. They are also suitable for candle making. They can come into contact with various materials, including: beeswax, ceramic plaster, epoxy resin, soy wax, soap base, creative cement, paraffin, and palm wax.

Flexible silicone soap mold

Dimensions: 23.5 cm x 8 cm x 24.4 cm

They are reusable and dishwasher safe. They are also suitable for candle making. They can come into contact with various materials, including: beeswax, ceramic plaster, epoxy resin, soy wax, soap base, creative cement, paraffin, and palm wax.

Flexible silicone soap mold

Dimensions: 23.5 cm x 8 cm x 24.4 cm

They are reusable and dishwasher safe. They are also suitable for candle making. They can come into contact with various materials, including: beeswax, ceramic plaster, epoxy resin, soy wax, soap base, creative cement, paraffin, and palm wax.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Height: 50 mm Wax weight: 20 g Recommended wick: 2 mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Height: 50 mm Wax weight: 20 g Recommended wick: 2 mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Height: 50 mm Wax weight: 20 g Recommended wick: 2 mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Silicone candle mold with PRINTED CUBE 60 mmMold height: 60 mm - Wick: 2 mm - Weight: 140 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Silicone candle mold with PRINTED CUBE 60 mmMold height: 60 mm - Wick: 2 mm - Weight: 140 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Silicone candle mold with PRINTED CUBE 60 mmMold height: 60 mm - Wick: 2 mm - Weight: 140 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Mold height: 80 mm - Diameter: 30 mm - Wick: 3 mm - Weight: 30 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Mold height: 80 mm - Diameter: 30 mm - Wick: 3 mm - Weight: 30 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Mold height: 80 mm - Diameter: 30 mm - Wick: 3 mm - Weight: 30 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold with wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold with wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Silicone candle mold with STRAIGHT STEL 20 cmMold height: 200 mm - Diameter: 18 mm - Weight: 35 g - Wick: 3 mmSilicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Silicone candle mold with STRAIGHT STEL 20 cmMold height: 200 mm - Diameter: 18 mm - Weight: 35 g - Wick: 3 mmSilicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Silicone candle mold with STRAIGHT STEL 20 cmMold height: 200 mm - Diameter: 18 mm - Weight: 35 g - Wick: 3 mmSilicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Height: 75 mm - Wax weight: 80 g - Recommended wick: 2 mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Height: 75 mm - Wax weight: 80 g - Recommended wick: 2 mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Height: 75 mm - Wax weight: 80 g - Recommended wick: 2 mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Height: 75 mm Wax weight: 25 g Recommended wick: 2 mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Height: 75 mm Wax weight: 25 g Recommended wick: 2 mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Height: 75 mm Wax weight: 25 g Recommended wick: 2 mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Silicone spray for spraying on candle molds for easy extraction 400 ml size

Silicone spray for spraying on candle molds for easy extraction 400 ml size

Silicone spray for spraying on candle molds for easy extraction 400 ml size

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Silicone mold in the shape of a sitting teddy bearMold height: 7 cm - Weight: 35 g Wick: 2 mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Silicone mold in the shape of a sitting teddy bearMold height: 7 cm - Weight: 35 g Wick: 2 mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Silicone mold in the shape of a sitting teddy bearMold height: 7 cm - Weight: 35 g Wick: 2 mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Silicone candle mold with SMALL BALEMold height: 70 mm - Diameter: 70 mm - Wick: 3 mm- Weight: 190 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Silicone candle mold with SMALL BALEMold height: 70 mm - Diameter: 70 mm - Wick: 3 mm- Weight: 190 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Silicone candle mold with SMALL BALEMold height: 70 mm - Diameter: 70 mm - Wick: 3 mm- Weight: 190 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Dimensions 22.5cm x 16cm. For use with special wicks art. HY T836 and HY T837 Silicone molds can be used for processing various raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Dimensions 22.5cm x 16cm. For use with special wicks art. HY T836 and HY T837 Silicone molds can be used for processing various raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Dimensions 22.5cm x 16cm. For use with special wicks art. HY T836 and HY T837 Silicone molds can be used for processing various raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Silicone candle mold with molded bee Height: 70 mm - Wax weight: 35 g - Recommended wick: 2 mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Silicone candle mold with molded bee Height: 70 mm - Wax weight: 35 g - Recommended wick: 2 mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Silicone candle mold with molded bee Height: 70 mm - Wax weight: 35 g - Recommended wick: 2 mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Mold height: 45 mm - Wick: 3 mm - Weight: 35 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene, epoxy, soap base. They are not suitable for food production.

Mold height: 45 mm - Wick: 3 mm - Weight: 35 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene, epoxy, soap base. They are not suitable for food production.

Mold height: 45 mm - Wick: 3 mm - Weight: 35 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene, epoxy, soap base. They are not suitable for food production.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Mold height: 90 mm - Diameter: 70 mm - Wick: 2 mm -Weight:200 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Mold height: 90 mm - Diameter: 70 mm - Wick: 2 mm -Weight:200 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Mold height: 90 mm - Diameter: 70 mm - Wick: 2 mm -Weight:200 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Silicone candle mold with small cube 45mmMold height: 45 mm - Wick: 3 mm - Weight: 85 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene, epoxy, soap base. They are not suitable for food production.

Silicone candle mold with small cube 45mmMold height: 45 mm - Wick: 3 mm - Weight: 85 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene, epoxy, soap base. They are not suitable for food production.

Silicone candle mold with small cube 45mmMold height: 45 mm - Wick: 3 mm - Weight: 85 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene, epoxy, soap base. They are not suitable for food production.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Mold height: 145 mmDiameter: 18 mmRecommended wick: 1.5 mmWeight: 20 gSilicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Mold height: 145 mmDiameter: 18 mmRecommended wick: 1.5 mmWeight: 20 gSilicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Mold height: 145 mmDiameter: 18 mmRecommended wick: 1.5 mmWeight: 20 gSilicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Dimensions 22.5cm x 16cm. For use with special wicks art. HY T836 and HY T837 Silicone molds can be used for processing various raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Dimensions 22.5cm x 16cm. For use with special wicks art. HY T836 and HY T837 Silicone molds can be used for processing various raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Dimensions 22.5cm x 16cm. For use with special wicks art. HY T836 and HY T837 Silicone molds can be used for processing various raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

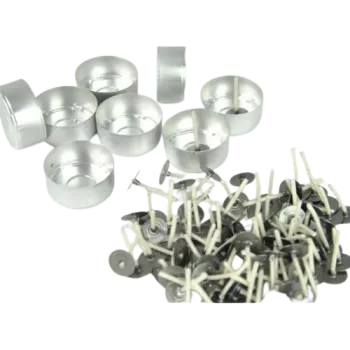

Set for lumino, consisting of: 30 aluminum containers and 30 wicks (30 threads)Aluminum containers diameter 35 mm height 15 mmWaxed wick 30 threadsReplace wick 30 threads (Cod. HY T836) and 39 threads (Cod. HY T837)Also available a wide range of dyes (Cod. HY BR) and fragrances (Cod. HY FRAGRANCE)

Set for lumino, consisting of: 30 aluminum containers and 30 wicks (30 threads)Aluminum containers diameter 35 mm height 15 mmWaxed wick 30 threadsReplace wick 30 threads (Cod. HY T836) and 39 threads (Cod. HY T837)Also available a wide range of dyes (Cod. HY BR) and fragrances (Cod. HY FRAGRANCE)

Set for lumino, consisting of: 30 aluminum containers and 30 wicks (30 threads)Aluminum containers diameter 35 mm height 15 mmWaxed wick 30 threadsReplace wick 30 threads (Cod. HY T836) and 39 threads (Cod. HY T837)Also available a wide range of dyes (Cod. HY BR) and fragrances (Cod. HY FRAGRANCE)

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Silicone gnome candle mold Height: 110mm - Weight: 0.790kg Wax weight: 155g - Wick: 3mm Mold diameter: 75mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Silicone gnome candle mold Height: 110mm - Weight: 0.790kg Wax weight: 155g - Wick: 3mm Mold diameter: 75mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Silicone gnome candle mold Height: 110mm - Weight: 0.790kg Wax weight: 155g - Wick: 3mm Mold diameter: 75mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Silicone mold for large molded bee candle Height: 155 mm - Wax weight: 50 g - Recommended wick: 2 mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Silicone mold for large molded bee candle Height: 155 mm - Wax weight: 50 g - Recommended wick: 2 mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Silicone mold for large molded bee candle Height: 155 mm - Wax weight: 50 g - Recommended wick: 2 mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold with wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold with wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Silicone mold for candle smooth cylinder (medium) Mold height: 120 mm - Wax weight: 205 g - Recommended wick: 2 mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Silicone mold for candle smooth cylinder (medium) Mold height: 120 mm - Wax weight: 205 g - Recommended wick: 2 mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Silicone mold for candle smooth cylinder (medium) Mold height: 120 mm - Wax weight: 205 g - Recommended wick: 2 mm Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Mold height: 60 mm - Wick: 3 mm - Weight: 30 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene, epoxy, soap base. They are not suitable for food production.

Mold height: 60 mm - Wick: 3 mm - Weight: 30 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene, epoxy, soap base. They are not suitable for food production.

Mold height: 60 mm - Wick: 3 mm - Weight: 30 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene, epoxy, soap base. They are not suitable for food production.

Wick made of paraffin-impregnated cotton filaments - wick height 25 mm with 3x10 weave, 30 strands, the more strands the wick has, the higher the flame.15 mm diameter tin base, 100% ready to usePack of 100 piecesBurn evenly and do not make smoke. They are ideal for both hobbyists and professionals.

Wick made of paraffin-impregnated cotton filaments - wick height 25 mm with 3x10 weave, 30 strands, the more strands the wick has, the higher the flame.15 mm diameter tin base, 100% ready to usePack of 100 piecesBurn evenly and do not make smoke. They are ideal for both hobbyists and professionals.

Wick made of paraffin-impregnated cotton filaments - wick height 25 mm with 3x10 weave, 30 strands, the more strands the wick has, the higher the flame.15 mm diameter tin base, 100% ready to usePack of 100 piecesBurn evenly and do not make smoke. They are ideal for both hobbyists and professionals.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Mold diameter: 4.7CM - Wax weight: 0.02 kg - Silicone weight: 0.05 kgCandle height: 1.8cm - Candle diameter: 3.5 cmRecommended wick: 2 mmSilicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base.They are not suitable for food production.

Mold diameter: 4.7CM - Wax weight: 0.02 kg - Silicone weight: 0.05 kgCandle height: 1.8cm - Candle diameter: 3.5 cmRecommended wick: 2 mmSilicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base.They are not suitable for food production.

Mold diameter: 4.7CM - Wax weight: 0.02 kg - Silicone weight: 0.05 kgCandle height: 1.8cm - Candle diameter: 3.5 cmRecommended wick: 2 mmSilicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base.They are not suitable for food production.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Silicone candle mold with CUBE 95mmMold height: 95 mm - Wick: 3 mm - Weight: 330 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Silicone candle mold with CUBE 95mmMold height: 95 mm - Wick: 3 mm - Weight: 330 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Silicone candle mold with CUBE 95mmMold height: 95 mm - Wick: 3 mm - Weight: 330 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Wick made of paraffin-impregnated cotton filaments - wick height 25 mm with 3x13 weave - 39 threads, The more threads the wick has, the higher the flame.15 mm diameter tin base, 100% ready to usePack of 100 piecesBurn evenly and do not make smoke. They are ideal for both hobbyists and professionals.

Wick made of paraffin-impregnated cotton filaments - wick height 25 mm with 3x13 weave - 39 threads, The more threads the wick has, the higher the flame.15 mm diameter tin base, 100% ready to usePack of 100 piecesBurn evenly and do not make smoke. They are ideal for both hobbyists and professionals.

Wick made of paraffin-impregnated cotton filaments - wick height 25 mm with 3x13 weave - 39 threads, The more threads the wick has, the higher the flame.15 mm diameter tin base, 100% ready to usePack of 100 piecesBurn evenly and do not make smoke. They are ideal for both hobbyists and professionals.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Mold height: 30 mm - Wick: 3 mm - Weight: 20 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene, epoxy, soap base. They are not suitable for food production.

Mold height: 30 mm - Wick: 3 mm - Weight: 20 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene, epoxy, soap base. They are not suitable for food production.

Mold height: 30 mm - Wick: 3 mm - Weight: 20 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene, epoxy, soap base. They are not suitable for food production.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Silicone candle mold with Beehives Straw 90 mm Mold height: 90 mm - Wick: 3 mm - Weight: 75 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base.They are not suitable for food production.

Silicone candle mold with Beehives Straw 90 mm Mold height: 90 mm - Wick: 3 mm - Weight: 75 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base.They are not suitable for food production.

Silicone candle mold with Beehives Straw 90 mm Mold height: 90 mm - Wick: 3 mm - Weight: 75 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base.They are not suitable for food production.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Mold height: 50 mm - Wick: 3 mm - Wax weight : 15 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Mold height: 50 mm - Wick: 3 mm - Wax weight : 15 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Mold height: 50 mm - Wick: 3 mm - Wax weight : 15 g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.

Mold height: 50mm diameter 60mm - wick 1.5mm - Wax weight 80g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Mold height: 50mm diameter 60mm - wick 1.5mm - Wax weight 80g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Mold height: 50mm diameter 60mm - wick 1.5mm - Wax weight 80g Silicone molds can be used for processing different raw materials: beeswax, soy wax, palm wax, kerosene wax, epoxy resin, soap base. They are not suitable for food production.

Woven white cotton candle wick in skeins -LENGTH 20 metersWick diameter: 1.5 - 2 - 3 mm in choice

Woven white cotton candle wick in skeins -LENGTH 20 metersWick diameter: 1.5 - 2 - 3 mm in choice

Woven white cotton candle wick in skeins -LENGTH 20 metersWick diameter: 1.5 - 2 - 3 mm in choice

To make your own beeswax candle you will need: - a silicone mold- a wick of appropriate thickness- a rubber band- a toothpick- silicone (Spray) - optional 1) Preparing the mold:We recommend spraying the mold inside with silicone spray which will make it easier to remove the candle at the end of the process. Insert the wick in the center from the bottom and pop it out from the top. Secure the mold with rubber bands to keep it tightly closed. Tie a wick to the toothpick and rest the latter on the top edge. 2) Fill the mold ocn the wax: Melt the wax in a preferably enameled pot, pour it into the mold when it has reached a temperature of 50°C. Pour it slowly into the mold. The time for the wax to solidify depends on the size of the mold and the amount of wax used. 3) Take the candle out of the mold:When the wax is cold, remove the rubber bands, open the mold and take out the candle. Remove the toothpick and cut the wick at the base of the candle, while on the top leave the wick 1 cm long. Spray the candle with silicone spray to give it shine.