Benchtop and professional uncapping machines

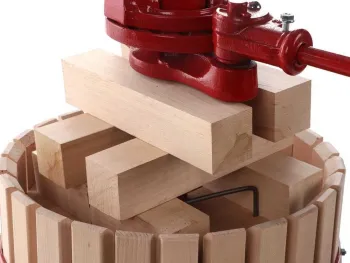

Manual device that facilitates the uncapping process.

Made of stainless steel and polyamide suitable for food use.

Dimensions:

Does not require electricity or steam.

Easy to install.

Manual device that facilitates the uncapping process.

Made of stainless steel and polyamide suitable for food use.

Dimensions:

Does not require electricity or steam.

Easy to install.

Manual device that facilitates the uncapping process.

Made of stainless steel and polyamide suitable for food use.

Dimensions:

Does not require electricity or steam.

Easy to install.

Manually operated DISOPERCULATOR-the honeycomb passes through 2 rollers that etch the operculoper Dadant B. brood and Honey super combs and Langstroth combs

Manually operated DISOPERCULATOR-the honeycomb passes through 2 rollers that etch the operculoper Dadant B. brood and Honey super combs and Langstroth combs

Manually operated DISOPERCULATOR-the honeycomb passes through 2 rollers that etch the operculoper Dadant B. brood and Honey super combs and Langstroth combs

With this machine complete in every part, it will be possible to speed up uncapping and use the Extractor effectively. The output of the machine, is a minimum of 150 frames per hour, but you can get up to 250 frames per hour. Uncapping is carried out by knives placed parallel to the two sides of the frames, simultaneously on both sides.Due to the special structure of the blades, the cells are not damaged and therefore no deposits are formed on the blades.It does not require any kind of heating. The adjustment of the blades to the various frame sizes is done quickly, with a simple movement. The blades do not touch the slats of the frames but do not move within them, so no damage is generated on either the blades or the frames. The distance between the blades can also be easily adjusted during operation with the foot pedal or hand lever. The cut wax falls into a collection container equipped with a filter, and from here the honey then drips into the lower part of the container. It is also equipped with a convenient Honey super stand. It is available with 12 V or 230 V motor.

With this machine complete in every part, it will be possible to speed up uncapping and use the Extractor effectively. The output of the machine, is a minimum of 150 frames per hour, but you can get up to 250 frames per hour. Uncapping is carried out by knives placed parallel to the two sides of the frames, simultaneously on both sides.Due to the special structure of the blades, the cells are not damaged and therefore no deposits are formed on the blades.It does not require any kind of heating. The adjustment of the blades to the various frame sizes is done quickly, with a simple movement. The blades do not touch the slats of the frames but do not move within them, so no damage is generated on either the blades or the frames. The distance between the blades can also be easily adjusted during operation with the foot pedal or hand lever. The cut wax falls into a collection container equipped with a filter, and from here the honey then drips into the lower part of the container. It is also equipped with a convenient Honey super stand. It is available with 12 V or 230 V motor.

Semiautomatic Konigin stainless steel uncapping machine, complete with operculum collecting tank, frame rack and honeycomb holderMachine size: 120x100x160 cm - Weight 70 KgElectrical power supply: 230V-50Hz

Semiautomatic Konigin stainless steel uncapping machine, complete with operculum collecting tank, frame rack and honeycomb holderMachine size: 120x100x160 cm - Weight 70 KgElectrical power supply: 230V-50Hz

Semiautomatic Konigin stainless steel uncapping machine, complete with operculum collecting tank, frame rack and honeycomb holderMachine size: 120x100x160 cm - Weight 70 KgElectrical power supply: 230V-50Hz

UNCOVERING MACHINE with alternating knives for Honey super combs -automatic honeycomb uncapping cycle-(one motor for two knives) TIG-welded stainless steel supporting structure 0.75Kw 230V knife handling motor.Honeycomb hauling motor 100W Two knives for cold cutting of the operculum,with alternating system Adjustment of cutting flush with wood or as desired Honeycomb coverer for combs with thickness from 22 to 35mm in automatic frame height adjustable support Automatic uncapping cycle for each individual honeycomb Run/stop/emergency button Hand protection barriers with cycle stop system OPTIONALS: automatic honeycomb unloading with accumulator for 5 uncapped combs. Air supply 6 bar, pressure regulator supplied Standard D.B. Honeycombs Power supply 230v 1000W OPTIONAL: Honeycomb unloader with accumulator for 5 uncapped honeycombs-pneumatic,including pressure regulator to be combined with uncapping machine

UNCOVERING MACHINE with alternating knives for Honey super combs -automatic honeycomb uncapping cycle-(one motor for two knives) TIG-welded stainless steel supporting structure 0.75Kw 230V knife handling motor.Honeycomb hauling motor 100W Two knives for cold cutting of the operculum,with alternating system Adjustment of cutting flush with wood or as desired Honeycomb coverer for combs with thickness from 22 to 35mm in automatic frame height adjustable support Automatic uncapping cycle for each individual honeycomb Run/stop/emergency button Hand protection barriers with cycle stop system OPTIONALS: automatic honeycomb unloading with accumulator for 5 uncapped combs. Air supply 6 bar, pressure regulator supplied Standard D.B. Honeycombs Power supply 230v 1000W OPTIONAL: Honeycomb unloader with accumulator for 5 uncapped honeycombs-pneumatic,including pressure regulator to be combined with uncapping machine

DISOPERCULATOR with alternating knives for Honey super combs -automatic honeycomb uncapping cycle-(one motor for two knives)

DISOPERCULATOR with alternating knives for Honey super combs -automatic honeycomb uncapping cycle-(one motor for two knives)

DISOPERCULATOR with alternating knives for Honey super combs -automatic honeycomb uncapping cycle-(one motor for two knives)

Bench (QI B10C) made of TIG welded stainless steel,tank 156x48x47 H80 cm Rounded anti-cut tank edges 4 Robust stainless steel legs with plates for fixing to the ground(dowels and screws for fixing excluded) Sloping bottom with sump for total discharge honey Max speed 800 rpm Electronic control panel with keyboard and membrane Setting extraction cycles Reversing rotation castle Shutdown timer Capacity lt 30 Built completely in AISI 304 stainless steel Power supply 230 V 0.40 Kw Optionals -bag with filtering,tap QI R04,support for uncapping machine DISOPERCULATOR (QI D20A) with alternating knives for Honey super combs -automatic honeycomb uncapping cycle-(one motor for two knives) TIG welded stainless steel support structure 0.75Kw 230V knife handling motor.Honeycomb hauling motor 100W Two knives for cold cutting of the operculum,with alternating system Adjustment of cutting flush with wood or as desired Honeycomb coverer for combs with thickness from 22 to 35mm in automatic frame height adjustable support Automatic uncapping cycle for each individual honeycomb Run/stop/emergency button Hand protection barriers with cycle stop system OPTIONALS: automatic honeycomb unloading with accumulator for 5 uncapped combs. Air supply 6 bar, pressure regulator supplied Standard D.B. honeycombs Power supply 230V 1000W

Bench (QI B10C) made of TIG welded stainless steel,tank 156x48x47 H80 cm Rounded anti-cut tank edges 4 Robust stainless steel legs with plates for fixing to the ground(dowels and screws for fixing excluded) Sloping bottom with sump for total discharge honey Max speed 800 rpm Electronic control panel with keyboard and membrane Setting extraction cycles Reversing rotation castle Shutdown timer Capacity lt 30 Built completely in AISI 304 stainless steel Power supply 230 V 0.40 Kw Optionals -bag with filtering,tap QI R04,support for uncapping machine DISOPERCULATOR (QI D20A) with alternating knives for Honey super combs -automatic honeycomb uncapping cycle-(one motor for two knives) TIG welded stainless steel support structure 0.75Kw 230V knife handling motor.Honeycomb hauling motor 100W Two knives for cold cutting of the operculum,with alternating system Adjustment of cutting flush with wood or as desired Honeycomb coverer for combs with thickness from 22 to 35mm in automatic frame height adjustable support Automatic uncapping cycle for each individual honeycomb Run/stop/emergency button Hand protection barriers with cycle stop system OPTIONALS: automatic honeycomb unloading with accumulator for 5 uncapped combs. Air supply 6 bar, pressure regulator supplied Standard D.B. honeycombs Power supply 230V 1000W

Stainless steel professional uncapping bench (QI B10C) with legs 156x48x47 cm tank complete with centrifuge for 30 lt operculum electronic-230V 0.38 KW complete with : DISOPERCULATOR (QI D20A) with alternating knives for Honey super combs-automatic honeycomb uncapping cycle-(one motor for two knives)

Stainless steel professional uncapping bench (QI B10C) with legs 156x48x47 cm tank complete with centrifuge for 30 lt operculum electronic-230V 0.38 KW complete with : DISOPERCULATOR (QI D20A) with alternating knives for Honey super combs-automatic honeycomb uncapping cycle-(one motor for two knives)

Stainless steel professional uncapping bench (QI B10C) with legs 156x48x47 cm tank complete with centrifuge for 30 lt operculum electronic-230V 0.38 KW complete with : DISOPERCULATOR (QI D20A) with alternating knives for Honey super combs-automatic honeycomb uncapping cycle-(one motor for two knives)

**MACHINE MANUFACTURED FOR DADANT BLATT FRAMES. UPON REQUEST, UPON RECEIPT OF MEASUREMENTS, IT CAN ALSO BE MADE FOR OTHER FRAMES.

The knives are heated by a hot water heating and recycling unit (included with the machine), and the knife temperature can be adjusted using a dedicated thermostat. The knives also operate inside the wooden frame of the combs and can therefore uncap even half-full frames. Adjusting the knives is quick and easy using a lever on the side of the uncapping machine, which allows you to narrow or widen the gap between the knives. Manually introduced frames are guided and automatically inserted between the blades to ensure regular and consistent uncapping on both sides.

**MACHINE MANUFACTURED FOR DADANT BLATT FRAMES. UPON REQUEST, UPON RECEIPT OF MEASUREMENTS, IT CAN ALSO BE MADE FOR OTHER FRAMES.

The knives are heated by a hot water heating and recycling unit (included with the machine), and the knife temperature can be adjusted using a dedicated thermostat. The knives also operate inside the wooden frame of the combs and can therefore uncap even half-full frames. Adjusting the knives is quick and easy using a lever on the side of the uncapping machine, which allows you to narrow or widen the gap between the knives. Manually introduced frames are guided and automatically inserted between the blades to ensure regular and consistent uncapping on both sides.

Uncapping Machine (GN 170K) (machine only, no optional extras)

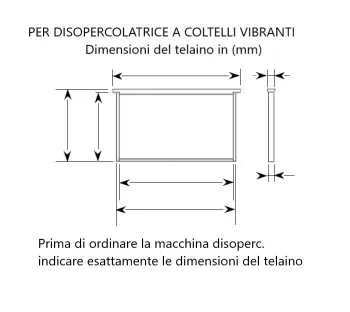

ALWAYS INDICATE THE FRAME DIMENSIONS

The "Giordan" heated vibrating knife uncapping machine is a professional machine that replaces the manual uncapping process. The machine is constructed entirely of AISI 304 stainless steel and works by guiding the frames through two water-heated vibrating knives, which ensure precise and optimal cutting of the cap. With the uncapping machine, the caps are not crumbled but cut, as with a manual knife.

We RECOMMEND adding the double blade kit; there is no need to re-clean the frames after the uncapping process.

DOUBLE KNIFE FINISHING BLADES KIT (Code GN GASGE000054)

Uncapping capacity: approximately 11 frames/minute. Knife temperature: thermostatically controlled from 30°C to 90°C. Power supply: 220 V. Power consumption: 2.8 kW 13.5 A.

DIM: Width 94 cm x Length 61.5 cm x Height 85 cm

Uncapping Machine (GN 170K) (machine only, no optional extras)

ALWAYS INDICATE THE FRAME DIMENSIONS

The "Giordan" heated vibrating knife uncapping machine is a professional machine that replaces the manual uncapping process. The machine is constructed entirely of AISI 304 stainless steel and works by guiding the frames through two water-heated vibrating knives, which ensure precise and optimal cutting of the cap. With the uncapping machine, the caps are not crumbled but cut, as with a manual knife.

We RECOMMEND adding the double blade kit; there is no need to re-clean the frames after the uncapping process.

DOUBLE KNIFE FINISHING BLADES KIT (Code GN GASGE000054)

Uncapping capacity: approximately 11 frames/minute. Knife temperature: thermostatically controlled from 30°C to 90°C. Power supply: 220 V. Power consumption: 2.8 kW 13.5 A.

DIM: Width 94 cm x Length 61.5 cm x Height 85 cm

Uncapping Machine (GN 170K) (machine only, no optional extras)

ALWAYS INDICATE THE FRAME DIMENSIONS

The "Giordan" heated vibrating knife uncapping machine is a professional machine that replaces the manual uncapping process. The machine is constructed entirely of AISI 304 stainless steel and works by guiding the frames through two water-heated vibrating knives, which ensure precise and optimal cutting of the cap. With the uncapping machine, the caps are not crumbled but cut, as with a manual knife.

We RECOMMEND adding the double blade kit; there is no need to re-clean the frames after the uncapping process.

DOUBLE KNIFE FINISHING BLADES KIT (Code GN GASGE000054)

Uncapping capacity: approximately 11 frames/minute. Knife temperature: thermostatically controlled from 30°C to 90°C. Power supply: 220 V. Power consumption: 2.8 kW 13.5 A.

DIM: Width 94 cm x Length 61.5 cm x Height 85 cm

Support frame (GN TDB)

Support frame (GN TDB) with 4 legs and wheels in AISI 304 steel, complete with stainless steel drain.

Dimensions: 87 x 180 x 98 cm

The support allows for the insertion of a 100, 120, or 150 cm uncapping table with wheels and a wax melter (not included).

**MACHINE MANUFACTURED FOR DADANT BLATT FRAMES. UPON REQUEST, UPON RECEIPT OF DIMENSIONS, IT CAN ALSO BE MADE FOR OTHER FRAMES.

The knives are heated by a hot water heating and recycling unit (included with the machine), and the knife temperature can be adjusted using a dedicated thermostat. The knives also operate inside the wooden frame of the honeycombs and can therefore uncap even half-full frames. Adjusting the blades is quick and easy using a lever on the side of the uncapping machine, which allows you to narrow or widen the gap between the blades. The manually inserted combs are automatically guided and inserted between the blades to ensure even and consistent uncapping on both sides. After the uncapping process, the frames slide into storage on the frame. An uncapping table can be positioned under the frame, as shown in the photo (the length of the frame varies based on the length of the table).

Support frame (GN TDB)

Support frame (GN TDB) with 4 legs and wheels in AISI 304 steel, complete with stainless steel drain.

Dimensions: 87 x 180 x 98 cm

The support allows for the insertion of a 100, 120, or 150 cm uncapping table with wheels and a wax melter (not included).

**MACHINE MANUFACTURED FOR DADANT BLATT FRAMES. UPON REQUEST, UPON RECEIPT OF DIMENSIONS, IT CAN ALSO BE MADE FOR OTHER FRAMES.

The knives are heated by a hot water heating and recycling unit (included with the machine), and the knife temperature can be adjusted using a dedicated thermostat. The knives also operate inside the wooden frame of the honeycombs and can therefore uncap even half-full frames. Adjusting the blades is quick and easy using a lever on the side of the uncapping machine, which allows you to narrow or widen the gap between the blades. The manually inserted combs are automatically guided and inserted between the blades to ensure even and consistent uncapping on both sides. After the uncapping process, the frames slide into storage on the frame. An uncapping table can be positioned under the frame, as shown in the photo (the length of the frame varies based on the length of the table).

Uncapping Machine (GN 170K) with Support Frame (GN TDB)

Lower table NOT included; please specify dimensions if you already have one.

The uncapping machine (GN 170K) with heated vibrating knives "o" is a professional machine that replaces the manual uncapping process. The machine is constructed entirely of AISI 304 stainless steel and works by guiding the frames through two water-heated vibrating knives, allowing for precise and optimal cutting of the cap.

We RECOMMEND adding the double blade kit; there is no need to re-clean the frames after the uncapping process.

DOUBLE KNIFE FINISHING BLADES KIT (Code GN GASGE000054)

Uncapping capacity: approximately 11 frames/minute.

Knife temperature: thermostatically controlled from 30°C to 90°C.

Power supply: 220 V. Power consumption: 2.8 kW 13.5 A.

Dimensions: 94 x 61.5 x 85 cm.

Uncapping Machine (GN 170K) with Support Frame (GN TDB)

Lower table NOT included; please specify dimensions if you already have one.

The uncapping machine (GN 170K) with heated vibrating knives "o" is a professional machine that replaces the manual uncapping process. The machine is constructed entirely of AISI 304 stainless steel and works by guiding the frames through two water-heated vibrating knives, allowing for precise and optimal cutting of the cap.

We RECOMMEND adding the double blade kit; there is no need to re-clean the frames after the uncapping process.

DOUBLE KNIFE FINISHING BLADES KIT (Code GN GASGE000054)

Uncapping capacity: approximately 11 frames/minute.

Knife temperature: thermostatically controlled from 30°C to 90°C.

Power supply: 220 V. Power consumption: 2.8 kW 13.5 A.

Dimensions: 94 x 61.5 x 85 cm.

Uncapping Machine (GN 170K) with Support Frame (GN TDB)

Lower table NOT included; please specify dimensions if you already have one.

The uncapping machine (GN 170K) with heated vibrating knives "o" is a professional machine that replaces the manual uncapping process. The machine is constructed entirely of AISI 304 stainless steel and works by guiding the frames through two water-heated vibrating knives, allowing for precise and optimal cutting of the cap.

We RECOMMEND adding the double blade kit; there is no need to re-clean the frames after the uncapping process.

DOUBLE KNIFE FINISHING BLADES KIT (Code GN GASGE000054)

Uncapping capacity: approximately 11 frames/minute.

Knife temperature: thermostatically controlled from 30°C to 90°C.

Power supply: 220 V. Power consumption: 2.8 kW 13.5 A.

Dimensions: 94 x 61.5 x 85 cm.

With the uncapping machine, the opercula are not crumbled but cut, as with the use of a hand knife. The knives are heated using a hot water heating and recycling unit (included with the machine), and the temperature of the knives can be adjusted using a special thermostat. The knives also work inside the wooden frame of the honeycombs and thus can uncapping even unfilled frames. Adjustment of the knives is quick and easy via a lever on the side of the uncapping machine that allows the passage between the knives to be tightened or widened. Manually introduced combs are guided and inserted, automatically between the blades in order to achieve regular and systematic uncapping on both sides. The press is constructed entirely of AISI 304 stainless steel and works cold through a perforated mesh containing an auger that presses the operculum. The press receives the operculum as soon as it is removed and divides it between wax and honey, going on to recover 90 percent of the product in a short time and thus avoiding the displacement of the operculum. The press is equipped with a simple and functional control panel where the speed controllers of the operculum-pressing auger with variable pitch are located.

With the uncapping machine, the opercula are not crumbled but cut, as with the use of a hand knife. The knives are heated using a hot water heating and recycling unit (included with the machine), and the temperature of the knives can be adjusted using a special thermostat. The knives also work inside the wooden frame of the honeycombs and thus can uncapping even unfilled frames. Adjustment of the knives is quick and easy via a lever on the side of the uncapping machine that allows the passage between the knives to be tightened or widened. Manually introduced combs are guided and inserted, automatically between the blades in order to achieve regular and systematic uncapping on both sides. The press is constructed entirely of AISI 304 stainless steel and works cold through a perforated mesh containing an auger that presses the operculum. The press receives the operculum as soon as it is removed and divides it between wax and honey, going on to recover 90 percent of the product in a short time and thus avoiding the displacement of the operculum. The press is equipped with a simple and functional control panel where the speed controllers of the operculum-pressing auger with variable pitch are located.

The DISOPRESS 2 is a professional compact machine consisting of the "Giordan" heated vibrating knife uncapping machine (code 170K) and the operculum press. DISOPRESS 2 is constructed entirely of AISI 304 stainless steel and works by guided passage of the frames inside two water-heated vibrating knives that allow for optimal operculum cutting. With the addition of the double blade kit, there is no need to go over the frames again after the uncapping process. Then, the operculum removed from the frames is discharged under the uncapping machine where the operculum press is installed. Uncapping capacity: about 11 frames/minute. Knife temperature: via thermostat from 30° C to 90° C. Power supply: 220 V (also possible in 380 V) Absorption: 3.50 KW **MACHINE PRODUCED FOR DADANT BLATT frames.

The DISOPRESS 2 is a professional compact machine consisting of the "Giordan" heated vibrating knife uncapping machine (code 170K) and the operculum press. DISOPRESS 2 is constructed entirely of AISI 304 stainless steel and works by guided passage of the frames inside two water-heated vibrating knives that allow for optimal operculum cutting. With the addition of the double blade kit, there is no need to go over the frames again after the uncapping process. Then, the operculum removed from the frames is discharged under the uncapping machine where the operculum press is installed. Uncapping capacity: about 11 frames/minute. Knife temperature: via thermostat from 30° C to 90° C. Power supply: 220 V (also possible in 380 V) Absorption: 3.50 KW **MACHINE PRODUCED FOR DADANT BLATT frames.

The DISOPRESS 2 is a professional compact machine consisting of the "Giordan" heated vibrating knife uncapping machine (code 170K) and the operculum press. DISOPRESS 2 is constructed entirely of AISI 304 stainless steel and works by guided passage of the frames inside two water-heated vibrating knives that allow for optimal operculum cutting. With the addition of the double blade kit, there is no need to go over the frames again after the uncapping process. Then, the operculum removed from the frames is discharged under the uncapping machine where the operculum press is installed. Uncapping capacity: about 11 frames/minute. Knife temperature: via thermostat from 30° C to 90° C. Power supply: 220 V (also possible in 380 V) Absorption: 3.50 KW **MACHINE PRODUCED FOR DADANT BLATT frames.

The knives are heated via a hot water heating and recycling unit (included with the machine), and the temperature of the knives can be adjusted via a special thermostat. The knives also work inside the wooden frame of the honeycombs and thus can uncapping even unfilled frames. Adjustment of the knives is quick and easy via a lever on the side of the uncapping machine that allows the passage between the knives to be tightened or widened. Manually introduced combs are guided and inserted, automatically between the blades in order to achieve smooth and systematic uncapping on both sides. Following the uncapping process, the frames are stored by sliding on the frame. An uncapping bench can be placed under the frame as in the photo (the length of the frame varies according to the length of the bench). The direct melter is equipped with a dual control (one for controlling the temperature of the honey, and the other for adjusting the temperature of the operculum melt) and dual discharge (one dedicated to honey and the other for wax discharge). The machine is equipped with a simple and functional control panel. And it is built with a double heated chamber. Following careful analysis and evaluation, the use of heat to melt the wax does not alter the freshness index of the honey and its state of preservation. Therefore, it was found that, in the honeys of the fondicera, the recorded HFM values are far below the threshold stipulated by the relevant regulations (L.D. No.179/2004). See attached report for further information. Uncapping capacity: about 11 frames/minute. Knife temperature: via thermostat from 30° C to 90° C. Power supply: 220 V (also possible in 380 V) Absorption: 8.8 KW **MACHINE PRODUCED FOR DADANT BLATT CANVAS.

The knives are heated via a hot water heating and recycling unit (included with the machine), and the temperature of the knives can be adjusted via a special thermostat. The knives also work inside the wooden frame of the honeycombs and thus can uncapping even unfilled frames. Adjustment of the knives is quick and easy via a lever on the side of the uncapping machine that allows the passage between the knives to be tightened or widened. Manually introduced combs are guided and inserted, automatically between the blades in order to achieve smooth and systematic uncapping on both sides. Following the uncapping process, the frames are stored by sliding on the frame. An uncapping bench can be placed under the frame as in the photo (the length of the frame varies according to the length of the bench). The direct melter is equipped with a dual control (one for controlling the temperature of the honey, and the other for adjusting the temperature of the operculum melt) and dual discharge (one dedicated to honey and the other for wax discharge). The machine is equipped with a simple and functional control panel. And it is built with a double heated chamber. Following careful analysis and evaluation, the use of heat to melt the wax does not alter the freshness index of the honey and its state of preservation. Therefore, it was found that, in the honeys of the fondicera, the recorded HFM values are far below the threshold stipulated by the relevant regulations (L.D. No.179/2004). See attached report for further information. Uncapping capacity: about 11 frames/minute. Knife temperature: via thermostat from 30° C to 90° C. Power supply: 220 V (also possible in 380 V) Absorption: 8.8 KW **MACHINE PRODUCED FOR DADANT BLATT CANVAS.

DISOMELTER is a compact professional machine consisting of the "Giordan" heated vibrating knife uncapping machine (code 170K) and the direct melter. The machine is constructed entirely of AISI 304 stainless steel and works by guided passage of the frames inside two water-heated vibrating knives that allow for precise and optimal cutting of the operculum. With the uncapping machine, the opercula are not crumbled but cut, as with the use of a manual knife. With the addition of the double blade kit, there is no need to go over the frames again after the uncapping process. The operculum is then collected in the direct fondicera below the uncapping machine. It has the function of separating the operculum from the honey and directly generating molten wax. The result will be the outflow, from two separate drains, of clean melted wax and honey.

DISOMELTER is a compact professional machine consisting of the "Giordan" heated vibrating knife uncapping machine (code 170K) and the direct melter. The machine is constructed entirely of AISI 304 stainless steel and works by guided passage of the frames inside two water-heated vibrating knives that allow for precise and optimal cutting of the operculum. With the uncapping machine, the opercula are not crumbled but cut, as with the use of a manual knife. With the addition of the double blade kit, there is no need to go over the frames again after the uncapping process. The operculum is then collected in the direct fondicera below the uncapping machine. It has the function of separating the operculum from the honey and directly generating molten wax. The result will be the outflow, from two separate drains, of clean melted wax and honey.

DISOMELTER is a compact professional machine consisting of the "Giordan" heated vibrating knife uncapping machine (code 170K) and the direct melter. The machine is constructed entirely of AISI 304 stainless steel and works by guided passage of the frames inside two water-heated vibrating knives that allow for precise and optimal cutting of the operculum. With the uncapping machine, the opercula are not crumbled but cut, as with the use of a manual knife. With the addition of the double blade kit, there is no need to go over the frames again after the uncapping process. The operculum is then collected in the direct fondicera below the uncapping machine. It has the function of separating the operculum from the honey and directly generating molten wax. The result will be the outflow, from two separate drains, of clean melted wax and honey.